- Screen Printing Machine

- Belt Size

- Machine Size

- Power

- Size

- 12 X 18 In (2)

- 16 X 20 In (4)

- 17.7\ (5)

- 18 X 12in (5)

- 18x12in (478)

- 20 X 24 In (16)

- 21.7 X 17.7 In (8)

- 21.7\ (9)

- 21.7in X 17.7in (2)

- 21.7x17.7 (4)

- 21.7x17.7 Inch (25)

- 22 X 18 Inch (2)

- 22x18 In (31)

- 24.8\ (6)

- 24\ (3)

- 32*7.9*75\ (6)

- 35.8\ (3)

- 4 Color 1 Station (6)

- 55x45cm (32)

- Medium (up To 36in.) (3)

- ... (2088)

- Type

- 3d Printer (4)

- 3d Printers (2)

- 4 Color 4 Station (7)

- Conveyor Dryer (6)

- Dtg Pretreat Machine (6)

- Equipment (401)

- Exposure Light (17)

- Exposure Unit (5)

- Flash Dryer (33)

- Label Printer (5)

- Monochrome Printer (3)

- Printing Equipment (4)

- Screen / Frame (9)

- Screen Printer (6)

- Screen Printing (9)

- Silk Screen Kit (509)

- Stretcher (11)

- Tool / Accessories (4)

- Vacuum Exposure Unit (24)

- Washout Booth (5)

- ... (1668)

- Voltage

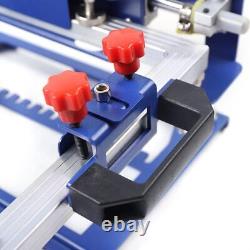

HinLIaDa Curved Screen Printing Machine, Manual Cylinder Press Curved Screen

The machine adopts a left-right push-pull structure; the mounting parts can be adjusted according to needs, suitable for left-handed or right-handed operation; 2, the machine adjusts and positions the height of the rear main frame. The rear main beam is adjusted up and down according to the height of the substrate by adjusting the post screw. The up and down adjustment range is 200 mm.

It can print cylindrical and conical products with a diameter of 170 mm. The printing frame of the substrate is designed to move forward and backward, and the three fixed aluminum strips at the bottom are directly installed on the base. The aluminum strip can move 290 mm from side to side; Positioning bracket mounting strip.

The three mounting strips can be moved left and right as needed, and they are locked in 19 U-shaped holes at the front and back of the base (each hole is 15 mm apart) to ensure accurate positioning of the mounting strips. Displacement of the mounting bar: Loosen the two screws of the mounting bar, push the mounting bar to the rear of the machine to the long hole, move the mounting bar to the left and right, and then move the mounting bar to the fixed U-shaped slot, tighten the two screws Positioning is complete. 4, three sets of substrates are used to place the rollers, which are metal bearing rollers (diameter 19 mm); nylon bearing rollers (diameter 25 mm); plastic bearing rollers (diameter 50 mm), which can be replaced by users as needed.Three rollers can be installed on the main frame and the accessory frame. 4 additional mounting brackets, remove the bearings on the original main mounting bracket, and directly fix the additional mounting bracket on the main mounting with screws, mainly used for the printing of conical products. The additional mounting bracket can be moved up and down by 20 mm. This curved screen printing machine is mainly used to print cylindrical and conical products with a diameter of less than 170mm.

It is suitable for printing height of 200mm; the inner length of the pattern is 150mm; it is suitable for a stencil with an outer diameter of 260450mm and a thickness of 35mm. For cylindrical and conical products, the printing surface has large bumps, and the printing surface has non-planar pits, which are not suitable for printing with this machine.

Three sets of base materials are used to place the rollers, all of which are metal bearing rollers (diameter 19mm); nylon bearing rollers (diameter 25mm); plastic bearing rollers (diameter 50mm), which can be replaced by users as needed. Three rollers can be installed on the main frame and the sub frame.

The curved screen printing machine is mainly used for cylindrical and conical products; such as cylindrical and conical products made of various plastic, glass and metal materials, including wine bottles, medicine bottles, cosmetic bottles and other packaging bottles; Mark Cups, beer mugs, wine glasses and other cups; glass tubes, pens, ballpoint pens, fishing rods, bats and other small cylindrical products. Install the screen frame and adjust it to the appropriate height, and install the handle position according to the usage habits. Install the scraper and fix it 1-2 cm away from the pattern. Adjust the position of the screen frame and the roller bearing, place the printed matter on the wheel, and leave a certain distance between the screen frames. Make sure that the printed object is aligned with the squeegee. Adjust the position of the screen frame and pour the ink.